|

本公司生产近30类,计140多种搅拌器,从**常见的(包括已有的HB5标准,SB90标准各种搅拌器)到各种复杂形状或特殊用途的搅拌器。可按H/T2123-91标准的各种规格尺寸系列制造,也可根据用户生产工艺需求,代为设计制造各种特殊要求、特殊规格或特殊用途的搅拌器。

拌器型号标注方法:

|

|

| 材料代号 |

| 搅拌器轴孔径 |

| 搅拌器的外径, |

| 搅拌器型式代号 |

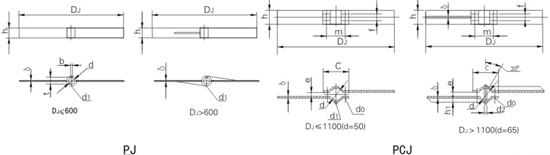

平直叶桨式搅拌器

平直叶整体桨式PJ、平直叶拆桨式PCJ

此类型为**基本的一种桨型,低速时为水平环流型,层流区操作:高速时为径流型。有挡板时,功率准数值Np明显升,为上下循环流,湍流加强,适用于低粘度液的混合、分散、固体悬浮、传热、液相反应等过程。μ<2000cp,n=1-100rpm,V=1-50m/s。常用规格DJ/D=0.35-0.8,h/DJ=0.10-0.25。当DJ/D=0.9以上时可设置多层桨叶,适用于高粘度液搅拌:降低桨叶离底部高度可作刮板用,防止重组份沉附底部。有用于悬浮、结晶与萃取等过程。

平直叶桨式搅拌器主要尺寸

| DJ |

d |

d0 |

d1 |

d2 |

δ |

h |

h1 |

b |

t |

C |

m |

f |

e |

N/n不大于 |

重量(kg) |

| 350 |

30 |

2-M12 |

M12 |

- |

10 |

40 |

- |

8 |

33.3 |

120 |

85 |

- |

3 |

0.01 |

1.77 |

| 400 |

30 |

2-M12 |

M12 |

- |

10 |

40 |

- |

8 |

33.3 |

120 |

85 |

- |

3 |

0.01 |

1.93 |

| 500 |

40 |

2-M12 |

M12 |

- |

12 |

50 |

- |

12 |

43.3 |

140 |

100 |

- |

3 |

0.02 |

3.38 |

| 550 |

40 |

2-M12 |

M12 |

- |

12 |

50 |

- |

12 |

43.3 |

140 |

100 |

- |

3 |

0.02 |

3.62 |

| 600 |

40 |

2-M12 |

M12 |

- |

12 |

60 |

- |

12 |

43.3 |

140 |

100 |

- |

3 |

0.025 |

4.59 |

| 700 |

50 |

4-M12 |

M12 |

- |

16 |

90 |

- |

14 |

53.8 |

140 |

110 |

45 |

5 |

0.06 |

10.42 |

| 850 |

50 |

4-M12 |

M12 |

- |

16 |

90 |

- |

14 |

53.8 |

140 |

110 |

45 |

5 |

0.075 |

12.11 |

| 950 |

50 |

4-M16 |

M16 |

- |

16 |

90 |

- |

14 |

53.8 |

150 |

110 |

45 |

5 |

0.075 |

13.57 |

| 1100 |

50 |

4-M16 |

M16 |

- |

16 |

120 |

- |

14 |

53.8 |

150 |

110 |

70 |

5 |

0.075 |

20.95 |

| 1100 |

65 |

4-M16 |

M16 |

16 |

14 |

120 |

50 |

18 |

69.4 |

170 |

130 |

70 |

7 |

0.2 |

24.25 |

| 1250 |

65 |

4-M16 |

M16 |

16 |

14 |

120 |

50 |

18 |

69.4 |

170 |

130 |

70 |

7 |

0.2 |

27.07 |

| 1250 |

80 |

4-M16 |

M16 |

16 |

14 |

150 |

60 |

22 |

85.4 |

190 |

150 |

90 |

7 |

0.35 |

34.04 |

| 1400 |

65 |

4-M16 |

M16 |

16 |

14 |

150 |

50 |

18 |

69.4 |

170 |

130 |

90 |

7 |

0.25 |

35.29 |

| 1400 |

80 |

4-M16 |

M16 |

16 |

16 |

150 |

60 |

22 |

85.4 |

200 |

160 |

90 |

7 |

0.35 |

43.10 |

| 1500 |

65 |

4-M16 |

M16 |

16 |

14 |

150 |

50 |

18 |

69.4 |

170 |

130 |

90 |

7 |

0.25 |

37.63 |

| 1500 |

80 |

4-M16 |

M16 |

16 |

16 |

150 |

60 |

22 |

85.4 |

200 |

160 |

90 |

7 |

0.35 |

45.52 |

| 1700 |

80 |

4-M16 |

M16 |

16 |

16 |

180 |

65 |

22 |

85.4 |

200 |

160 |

110 |

7 |

0.4 |

59.20 |

| 1700 |

95 |

4-M22 |

M22 |

22 |

18 |

180 |

80 |

25 |

100.4 |

220 |

170 |

110 |

7 |

0.75 |

75.20 |

| 1800 |

95 |

4-M22 |

M22 |

22 |

16 |

180 |

80 |

25 |

100.4 |

220 |

170 |

110 |

7 |

0.54 |

67.30 |

| 1800 |

110 |

4-M22 |

M22 |

22 |

20 |

180 |

80 |

28 |

116.4 |

250 |

200 |

110 |

9 |

1.0 |

85.37 |

| 2000 |

95 |

4-M22 |

M22 |

22 |

14 |

200 |

80 |

25 |

100.4 |

220 |

170 |

130 |

7 |

0.64 |

70.66 |

| 2000 |

110 |

4-M22 |

M22 |

22 |

16 |

200 |

80 |

28 |

116.4 |

250 |

200 |

130 |

9 |

0.8 |

80.49 |

| 2100 |

95 |

4-M22 |

M22 |

22 |

14 |

200 |

80 |

25 |

100.4 |

220 |

170 |

130 |

7 |

0.6 |

72.70 |

| 2100 |

110 |

4-M22 |

M22 |

22 |

18 |

200 |

80 |

28 |

116.4 |

250 |

200 |

130 |

9 |

1.0 |

86.90 |

| 2240 |

110 |

4-M22 |

M24 |

22 |

16 |

220 |

80 |

28 |

116.4 |

250 |

200 |

140 |

7 |

1.0 |

98.53 |

| 2240 |

130 |

4-M22 |

M24 |

22 |

18 |

220 |

80 |

32 |

137.4 |

270 |

220 |

140 |

9 |

1.6 |

112.1 |

| 2500 |

120 |

6-M22 |

M24 |

24 |

16 |

250 |

90 |

32 |

127.4 |

280 |

230 |

150 |

8 |

1.3 |

124.7 |

| 2500 |

140 |

6-M24 |

M24 |

24 |

18 |

250 |

90 |

36 |

148.4 |

290 |

250 |

150 |

10 |

2.0 |

141.0 |

| 2800 |

150 |

6-M22 |

M24 |

24 |

18 |

280 |

100 |

32 |

137.4 |

270 |

220 |

160 |

8 |

1.6 |

172.1 |

| 2800 |

150 |

6-M22 |

M30 |

24 |

20 |

280 |

100 |

36 |

158.4 |

300 |

260 |

160 |

10 |

2.5 |

193.9 |

| 3150 |

140 |

6-M22 |

M30 |

24 |

18 |

315 |

110 |

36 |

148.4 |

290 |

250 |

170 |

8 |

2.0 |

215.3 |

| 3150 |

160 |

6-M22 |

M30 |

28 |

20 |

315 |

110 |

40 |

169.4 |

310 |

270 |

170 |

10 |

3.0 |

241.2 |

| 3550 |

150 |

6-M22 |

M30 |

28 |

20 |

355 |

120 |

36 |

150.4 |

300 |

260 |

180 |

8 |

2.5 |

298.3 |

| 3550 |

170 |

6-M22 |

M30 |

28 |

22 |

355 |

120 |

40 |

179.4 |

320 |

280 |

180 |

10 |

3.6 |

330.6 |

备注:搅拌器内孔可根据用户要求制作,轮毂高度一般与内孔相一致。

|