|

本公司生产近30类,计140多种搅拌器,从**常见的(包括已有的HB5标准,SB90标准各种搅拌器)到各种复杂形状或特殊用途的搅拌器。可按H/T2123-91标准的各种规格尺寸系列制造,也可根据用户生产工艺需求,代为设计制造各种特殊要求、特殊规格或特殊用途的搅拌器。

搅拌器型号标注方法:

|

|

| 材料代号 |

| 搅拌器轴孔径 |

| 搅拌器的外径, |

| 搅拌器型式代号 |

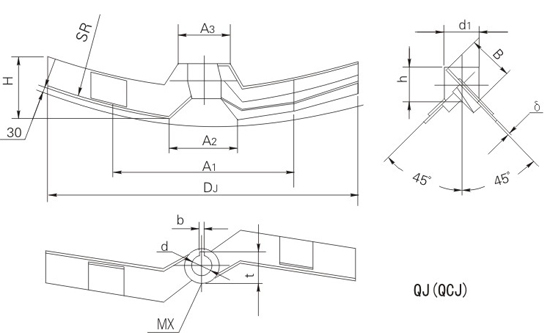

曲边斜边桨式

曲边斜叶整体桨式QJ、曲边斜边可拆桨式QCJ

本类搅拌器是斜叶桨式的变型,桨底旋转面接近容器的随圆面,桨叶平面与旋转轴垂直面又成一倾角45°,兼起刮板作用。操作多为低速范围,在层流区操作,常用介质粘度μ<2000cP,n=1-100rpm,v=1.0-5.0m/s。

| DJ |

d |

d1 |

h |

SR |

H |

A1 |

A2 |

A3 |

键槽 |

B |

MX |

δ |

重量 |

| b |

t |

不锈钢/碳钢 |

不锈钢 |

碳钢 |

| 200 |

25 |

50 |

35 |

350 |

35 |

/ |

50 |

40 |

8 |

28.3 |

30 |

8 |

3/4 |

0.605 |

0.666 |

| 220 |

25 |

50 |

35 |

400 |

38 |

/ |

55 |

44 |

8 |

28.3 |

33 |

8 |

3/4 |

0.639 |

0.712 |

| 250 |

30 |

65 |

40 |

450 |

42 |

/ |

60 |

50 |

8 |

33.3 |

38 |

8 |

4/6 |

1.239 |

1.444 |

| 280 |

35 |

70 |

45 |

500 |

48 |

/ |

70 |

56 |

10 |

38.3 |

40 |

8 |

4/6 |

1.506 |

1.744 |

| 320 |

35 |

70 |

45 |

550 |

55 |

/ |

80 |

64 |

10 |

38.3 |

50 |

10 |

6/8 |

2.081 |

2.426 |

| 360 |

40 |

75 |

50 |

650 |

60 |

/ |

90 |

70 |

12 |

43.3 |

55 |

10 |

6/8 |

2.571 |

2.987 |

| 400 |

40 |

80 |

55 |

700 |

68 |

/ |

100 |

80 |

12 |

43.3 |

60 |

10 |

8/10 |

3.915 |

4.466 |

| 450 |

45 |

85 |

60 |

800 |

75 |

/ |

110 |

90 |

14 |

48.8 |

65 |

10 |

8/10 |

4.626 |

5.280 |

| 500 |

50 |

90 |

70 |

90 |

85 |

300 |

125 |

100 |

14 |

53.8 |

75 |

12 |

10/12 |

6.761 |

7.597 |

| 560 |

55 |

95 |

80 |

1000 |

95 |

300 |

140 |

110 |

14 |

59.4 |

85 |

12 |

10/12 |

8.307 |

9.328 |

| 630 |

60 |

100 |

85 |

1100 |

105 |

350 |

160 |

120 |

18 |

64.4 |

95 |

12 |

12/14 |

11.42 |

12.71 |

| 710 |

65 |

105 |

95 |

1200 |

120 |

350 |

175 |

140 |

18 |

69.4 |

105 |

12 |

12/14 |

13.93 |

15.50 |

| 800 |

70 |

110 |

100 |

1400 |

135 |

400 |

200 |

160 |

20 |

74.9 |

120 |

12 |

14/16 |

19.04 |

21.02 |

| 900 |

75 |

120 |

110 |

1600 |

150 |

500 |

225 |

180 |

20 |

79.9 |

130 |

12 |

14/16 |

23.87 |

26.30 |

| 1000 |

80 |

140 |

120 |

1800 |

170 |

600 |

250 |

200 |

22 |

85.4 |

150 |

12 |

16/18 |

35.68 |

38.73 |

| 1120 |

85 |

150 |

130 |

2000 |

190 |

700 |

280 |

220 |

22 |

90.4 |

160 |

16 |

16/18 |

43.39 |

47.06 |

| 1250 |

90 |

160 |

150 |

2200 |

210 |

800 |

310 |

250 |

25 |

95.4 |

180 |

16 |

18/20 |

60.62 |

65.25 |

| 1400 |

100 |

180 |

170 |

2500 |

230 |

900 |

350 |

280 |

28 |

106.4 |

200 |

16 |

18/20 |

79.22 |

85.02 |

| 1600 |

110 |

190 |

180 |

2800 |

270 |

1000 |

400 |

320 |

28 |

116.4 |

230 |

16 |

18/20 |

101.4 |

109.0 |

| 1800 |

120 |

200 |

200 |

3200 |

300 |

1100 |

450 |

350 |

32 |

127.4 |

260 |

16 |

18/20 |

123.7 |

133.3 |

| 2000 |

130 |

210 |

220 |

3500 |

330 |

110 |

500 |

400 |

32 |

137.4 |

290 |

18 |

18/20 |

149.3 |

160.9 |

| 2240 |

140 |

220 |

245 |

4000 |

370 |

1200 |

560 |

440 |

36 |

148.4 |

320 |

18 |

18/20 |

182.1 |

196.5 |

| 2500 |

150 |

230 |

270 |

4500 |

420 |

1200 |

620 |

500 |

36 |

158.4 |

360 |

18 |

20/22 |

224.4 |

293.7 |

| 2800 |

160 |

240 |

300 |

5000 |

470 |

1200 |

700 |

560 |

40 |

169.4 |

400 |

20 |

20/22 |

275.8 |

293.7 |

| 3150 |

170 |

250 |

340 |

5600 |

530 |

1300 |

780 |

630 |

40 |

179.4 |

450 |

20 |

20/22 |

361.6 |

338.7 |

| 3550 |

180 |

260 |

380 |

630 |

590 |

1300 |

880 |

700 |

45 |

190.4 |

500 |

20 |

20/22 |

447.1 |

479.8 |

备注:搅拌器内孔可根据用户要求制作,轮晕高度一般与内孔相一致。

|